2003 Buick Regal. The check engine light is on, and the diagnostic tool is reporting a u1000 data link malfunction. What does this mean/what repairs need to be made?

SOURCE: obd1 scan tool will notaccess

A couple of ways to check and see if the computer is ok first:

check engine light must come onwith they in on position

The fuel pump must run for two (2) seconds with the key ON

There must be a 5 volt reference at sensors like map, TPS

Must communicate with scan tool

The ORANGE wires at the computer are you power input wires one has 12V all the time this is your KEEP ALIVE MEMORY

one is 12 with the Key on you MUAT HAVE VOLTAGE AT BOTH

Check the computers Ground most are out under the hood and are brown wires

Try the GM TAP TEST this is a factory authorized test with the computer connected and you verified all of the above SLAP the computer with the open hand firmly not too hard but firm see if anything changes,

Do not disconnect the battery you will erase all the codes!

Please contact me if you need any additional information.

If you find the information provided helpful please give me a good rating

www.aceautomotive1.com

SOURCE: how to replace a crank sensor on a 93 buick regal 3.8L engine

Im assuming this is the Series I 3800? If so, if you can email me I can send you some directions on the process. Its for a Series II 3800 but it should be similar. If you cant email me, post up and I'll see what I can do.

SOURCE: Check Engine light

that code definition is "Evap high purge flow fault". It means you may have a problem with the evaporative system. this system routes fuel fumes back to the fuel tank. If you want to try and clear this code, find the radio code for your car and then disconnect the battery for 30 seconds. Reconnect the battery and the check engine light should be out. You will then need the radio code to reset your car stereo. the check engine light may stay off if the condition was a transient one. If not, the light will come back on after you drive the car two drive cycles. That is: two starts, warm ups and shut downs. If the light returns, have a mechanic check it out.

SOURCE: Check engine light on. Code P0440.

wow thermostat >>>> shucks i believe its evep emissions code like faulty gas cap ....you can reset any computer the chck eng light will come on in 50 to 100 miles if not fixed....

SOURCE: 1999 buick regal odometer light fading

1999 buick custom century odometer light has gone out. what is the cost to repair? is there a simple way to repair or replace the lighting?

Step

Action

Yes

No

1

Install a scan tool.

Does the scan tool power up?

Does the scan tool communicate with the BCM?

Important: The engine may start during the following step. Turn OFF the engine as soon as you have observed the Crank power mode.

Does the Class 2 Power Mode parameter reading match the ignition switch position for all the selected positions?

Select the BCM display DTCs function on the scan tool.

Does the scan tool display any DTCs?

Does the scan tool display B1477 or B1478?

Go to Step 2

Go to Scan Tool Does Not Power Up in Data Link Communications

2

Go to Step 3

Go to Scan Tool Does Not Communicate with Class 2 Device in Data Link Communications

3

Go to Step 4

Go to Power Mode Mismatch in Body Control System

4

Go to Step 5

Go to the Symptoms list in the appropriate service category

5

Go to Diagnostic Trouble Code (DTC) List

Go to Symptoms - Retained Accessory Power

Control Module

ID Number

Body Control Module (BCM)

064

Electronic Brake Control Module (EBCM)

040

Instrument Panel Cluster (IPC)

096

Radio

128

Powertrain Control Module (PCM)

016

Sensing and Diagnostic Module (SDM)

088

Diagnostic Aids

When a malfunction such as a open fuse to a module occurs while modules are communicating, a Loss of Communication DTC is set as current. When the modules stop communicating, ignition is turned off, the current Loss Communication DTC is cleared but the history DTC remains. When the modules begin to communicate again, the ignition is turned on, the module with the open fuse will not be learned by the other modules so U1000 or U1255 is set current by the other modules. If the malfunction occurs when the modules are not communicating, only U1000 or U1255 is set.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

?€¢

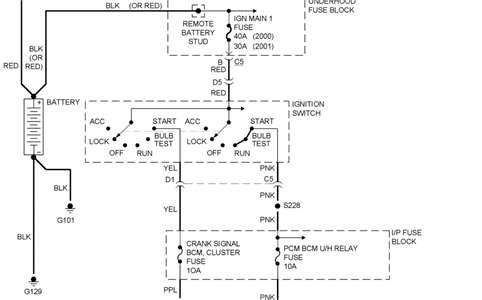

The switched battery positive supply circuits

?€¢

The battery positive voltage output circuits

?€¢

The ignition voltage input circuits

?€¢

The ignition voltage output circuits

Refer to the following:

?€¢

Control Module References in Body Control System for the applicable schematic

?€¢

Circuit Testing in Wiring Systems

?€¢

Wiring Repairs in Wiring Systems

Did you find and correct the condition?

5

Important: Inspect all connectors in the serial data communications circuit.

Refer to the following:

?€¢

Data Link Connector Schematics

?€¢

Testing for Intermittent Conditions and Poor Connections in Wiring Systems

?€¢

Connector Repairs in Wiring Systems

?€¢

Circuit Testing in Wiring Systems

?€¢

Wiring Repairs in Wiring Systems

Did you find and correct the condition?

Refer to the following:

Did you find and correct the condition?

Go to Step 8

Go to Step 6

6

Inspect the harness connector of the module that is not communicating for poor connections and terminal tension at the following circuits:

?€¢

The battery positive voltage input circuits

?€¢

The switched battery positive voltage supply

?€¢

The battery positive voltage output circuits

?€¢

The ignition voltage input circuits

?€¢

The ignition voltage output circuits

?€¢

The ground circuits

?€¢

The class 2 serial data circuits

?€¢

Control Module References in Body Control System for the applicable schematic

?€¢

Testing for Intermittent Conditions and Poor Connections in Wiring Systems

?€¢

Connector Repairs in Wiring Systems

Go to Step 8

Go to Step 7

7

Important: Perform the module programming or setup procedure if required.

Replace the module that is not communicating. Refer to Control Module References in Body Control System for the appropriate Repair Instructions for the module replacement.

Did you complete the replacement?

Go to Step 10

--

8

Does the scan tool display any DTCs which do not begin with a "U"?

Go to Control Module References in Body Control System for applicable Diagnostic System Check

Go to Step 9

9

Use the scan tool in order to clear the DTCs.

Did you complete the action?

Go to Step 10

--

10

Select the Display DTCs function for the modules which had U1000 or U1255 set as a current DTC.

Does the scan tool display DTCs which do not begin with a "U"?

Go to Control Module References in Body Control System for applicable Diagnostic System Check

Go to Step 11

11

Use the scan tool in order to clear the DTCs.

Did you complete the action?

System OK

--

12

Did you record any other DTCs for the modules which had U1000 or U1255 set as a current DTC?

Go to Control Module References in Body Control System for applicable Diagnostic System Check

Go to Step 13

13

?€¢

The ability of the control modules to communicate through the serial data circuit.

?€¢

The identification of any stored diagnostic trouble codes (DTCs) and their status.

The use of the Diagnostic System Check will identify the correct procedure for diagnosing the system and where the procedure is located.

Diagnostic System Check - Engine Electrical

Test Description

The numbers below refer to the step numbers on the diagnostic table.

Lack of communication may be due to a partial malfunction of the class 2 serial data circuit or due to a total malfunction of the class 2 serial data circuit. The specified procedure will determine the particular condition.

The symptom list in Symptoms will determine the correct diagnostic procedure to use.

The presence of DTCs which begin with "U" indicate some other module is not communicating. The specified procedure will compile all the available information before tests are performed.

Step

Action

Yes

No

1

Did you perform the Battery Inspection/Test?

Go to Step 2

Go to Battery Inspection/Test

2

Install a scan tool.

Does the scan tool power up?

Go to Step 4

Go to Scan Tool Does Not Power Up in Data Link Communications

3

Important: The engine may start during the following step. Turn OFF the engine as soon as you have observed the Crank power mode.

Access the Class 2 Power Mode in the Diagnostic Circuit Check on the scan tool.

Rotate the ignition switch through all positions while observing the Class 2 Power Mode on the Scan Tool. Refer to the Serial Data Power Mode table within the Body Control System Description and Operation in Body Control System for a list of the power mode states that correspond to each ignition switch position.

Does the Class 2 Power Mode parameter reading match the ignition switch position for all the selected positions?

Go to Step 4

Go to Power Mode Mismatch in Body Control System

4

Turn ON the ignition, with the engine OFF.

Attempt to communicate with each module on the class 2 serial data circuit:

• The body control module (BCM)

• The driver information center (DIC)

• The instrument panel cluster (IPC)

• The powertrain control module (PCM)

Does the scan tool communicate with any module on the class 2 serial data circuit?

Go to Step 5

Go to Scan Tool Does Not Communicate with Class 2 Device in Data Link Communications

5

Select the Display DTCs function for each module. If using a Tech 2, use the Class 2 DTC Check feature in order to determine which modules have DTCs set.

Record all of the displayed DTCs the DTC status and the module which set the DTC.

Does the scan tool display any DTCs?

Go to Step 6

Go to Symptoms - Engine Electrical

6

Does the scan tool display any DTC beginning with "U"?

Go to Diagnostic Trouble Code (DTC) List in Data Link Communications

Go to Step 7

7

Does the scan tool display any DTC beginning with "B"?

Go to Diagnostic Trouble Code (DTC) List in Body Control Systems

Go to Diagnostic Trouble Code (DTC)

?€¢

Scan tool power ground at terminal 4.

?€¢

Common signal ground at terminal 5.

?€¢

Class 2 signal at terminal 2.

I wonder how many friends out there mess up other friends vehicles from stuff they see on the internet . When are you people going to learn , your messing with complex electronics !!!!! He shorted out the class 2 serial data communication network !

Do you know what this is ? if not you need to take to your local GM Mr. goodwrench !

Class 2 Serial Data Link

The data link is configured as a ring with discrete lines entering and leaving each module. This allows communications to the modules on the ring if one of the two discrete circuits is open.

A total list of the control modules on the Class 2 Serial Data Line can include the following:

?€¢

Dash Integration Module (DIM)

?€¢

Driver Door Module (DDM)

?€¢

Electronic Brake Control Module (EBCM)

?€¢

Head Up Display (HUD) w/UV6

?€¢

HVAC Control Module w/C67

?€¢

Inflatable Restraint Sensing and Diagnostic Module (SDM)

?€¢

Instrument Panel Cluster (IPC)

?€¢

Instrument Panel Integration Module (IPM) w/CJ2

?€¢

Memory Seat Module (MSM) w/A45

?€¢

Powertrain Control Module (PCM)

?€¢

Radio

?€¢

Rear Integration Module (RIM)

?€¢

Remote Control Door Lock Receiver (RCDLR)

?€¢

Remote Playback Device - CD Changer w/U1S

?€¢

Theft Deterrent Control Module

?€¢

Vehicle Interface Unit (VIU) w/UE1

Power door serial data does not communicate with the scan tool via the DLC. Power door serial data information is interpreted by the driver door module (DDM) and transmitted on the Class 2 data link by the DDM.

Power door serial data is used for serial data communication between the four door modules as well as the driver door switch assembly (DDSA

Scan Tool Does Not Communicate with Class 2 Device

Modules connected to the class 2 serial data circuit monitor for serial data communications during normal vehicle operation. Operating information and commands are exchanged among the modules. Connecting a scan tool to the DLC allows communication with the modules for diagnostic purposes.

The engine will not start when there is a total malfunction of the class 2 serial data circuit while the engine is not running.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

?€¢

The powertrain control module (PCM)

?€¢

The instrument panel cluster

?€¢

The sensing diagnostic module (SDM)

?€¢

The electronic brake control module (EBCM)

The serial data line class 2 (circuit 1807) allows the scan tool to access directly the PCM in order to read emissions-related information. The scan tool gains access to both data lines through the data link connector (DLC). You may then monitor or control system operations for diagnostic purposes.

1,480 views

Usually answered in minutes!

no it doesn't.

×